Looking Good Info About How Do I Know If My MOSFET Is Defective

Mosfet Datasheet Everything You Need To Know

Is Your MOSFET Acting Up? A Guide to Spotting a Defective One

1. First Signs

So, your circuit isn't behaving as expected, and you suspect your MOSFET might be the culprit? Don't worry; it happens to the best of us. The MOSFET, or Metal-Oxide-Semiconductor Field-Effect Transistor, is a crucial component in many electronic circuits, acting like a tiny switch controlled by voltage. When it goes bad, things can get frustrating quickly. Let's dive into some ways to identify a potentially faulty MOSFET.

Think of your MOSFET like a valve controlling water flow. If the valve is stuck open or closed, the water isn't going where it needs to go. Similarly, a defective MOSFET might be permanently "on" (shorted) or permanently "off" (open), or it might just be switching erratically. This can lead to all sorts of weird circuit behavior, from components overheating to complete system failure.

Before you start tearing everything apart, observe the circuit in operation. Are there any visible signs of damage, like a burnt smell or a visibly cracked MOSFET package? These are obvious red flags. Also, pay attention to the temperature of the MOSFET. Is it running excessively hot compared to other components? This could indicate a problem.

Remember that time you tried that "shortcut" to fix something, and it ended up costing you more time and effort? Same principle here. Don't assume the MOSFET is bad just because something isn't working. Rule out other potential causes first, like faulty wiring, incorrect voltage levels, or problems with other components in the circuit. A little systematic troubleshooting can save you a lot of headaches.

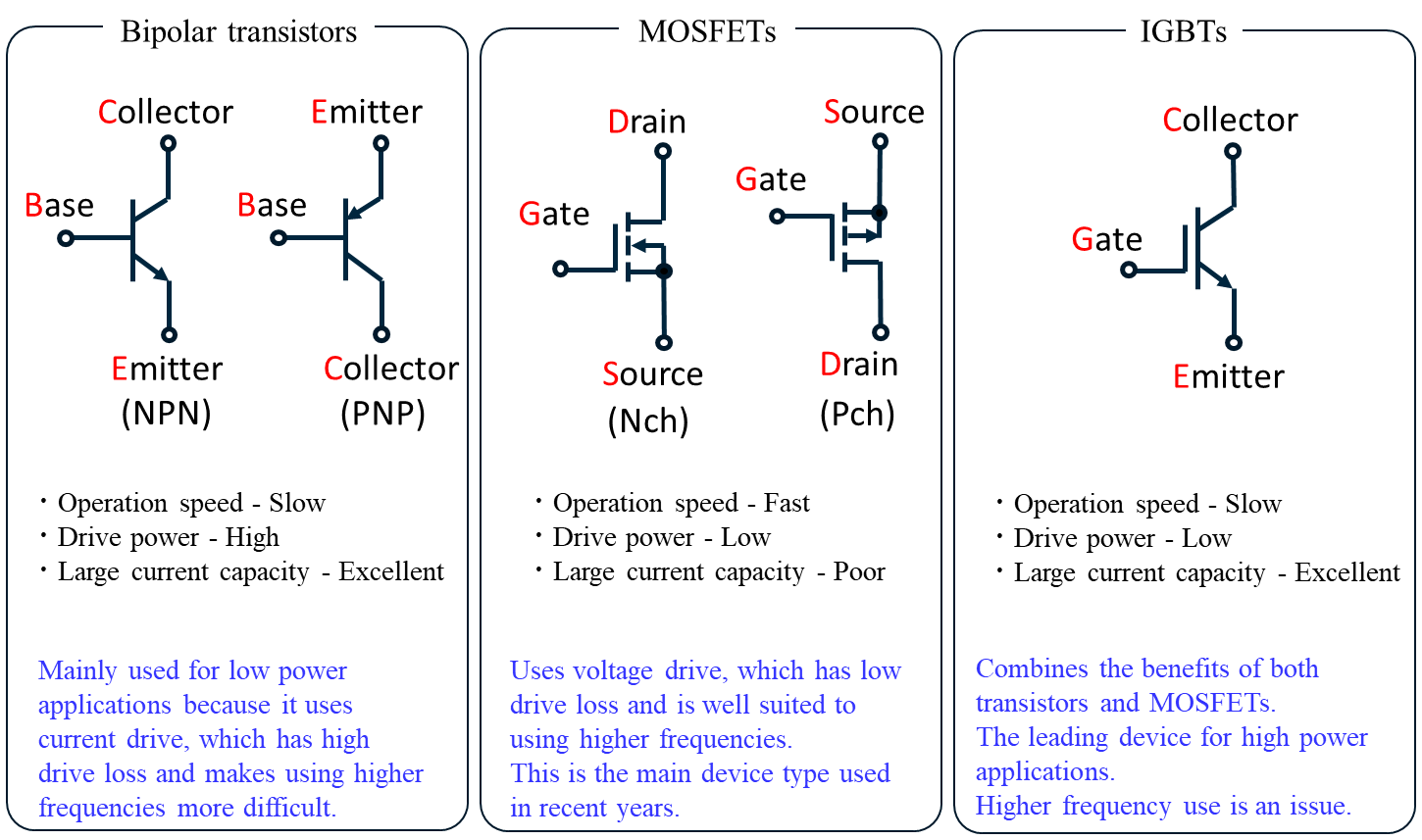

How To Pick Up A MOSFET For DIY, Characteristics Lesson 24

Testing the MOSFET

2. Getting Down to Business

Alright, let's get our hands dirty. The most common way to test a MOSFET is with a multimeter. This handy tool can measure resistance and voltage, which are key indicators of a MOSFET's health. Make sure your multimeter is set to measure resistance (Ohms Ω). Before you start, it's crucial to discharge any capacitors in the circuit to prevent damage to your multimeter or the MOSFET itself. Trust me, you don't want any unexpected sparks!

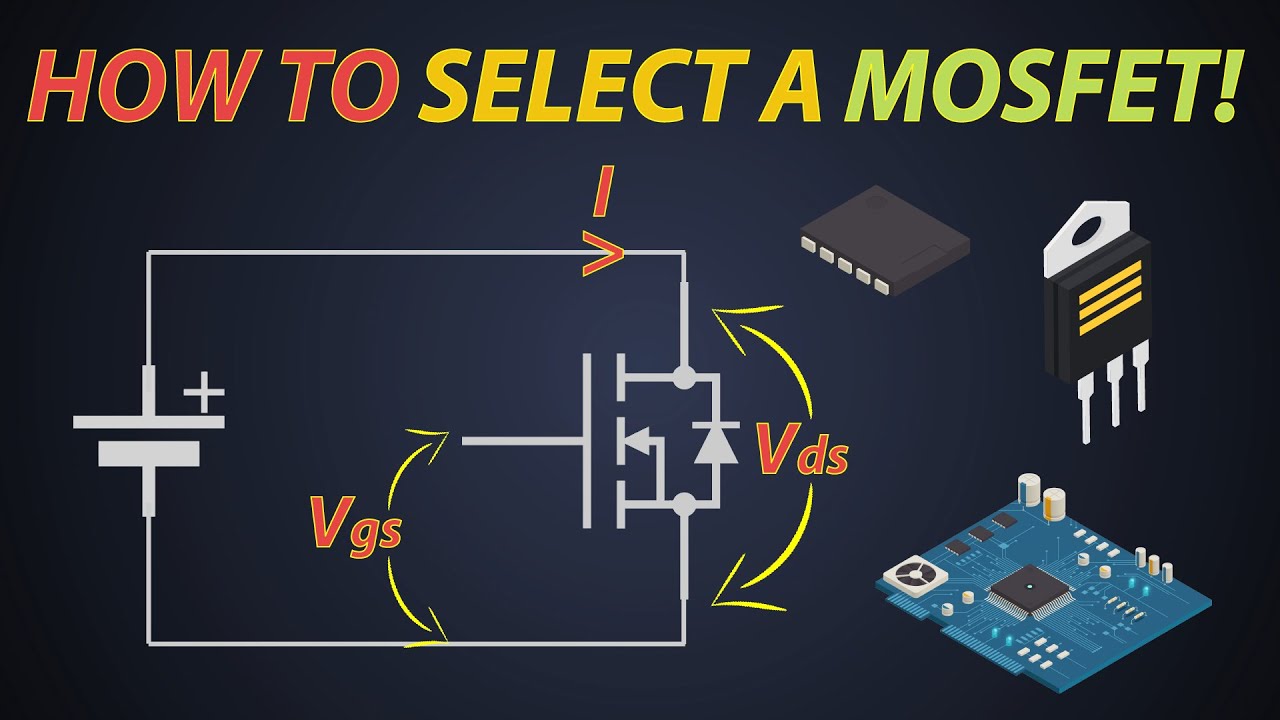

Now, identify the three terminals of your MOSFET: the Gate (G), the Drain (D), and the Source (S). These terminals are usually labeled on the datasheet or the component itself. Knowing which terminal is which is essential for accurate testing.

The basic test involves measuring the resistance between the various terminals. A healthy MOSFET should exhibit very high resistance between the Gate and the Source, and between the Gate and the Drain. A low resistance reading here suggests a short circuit, which indicates a defective MOSFET.

Think of the Gate as the control input. It shouldn't have a direct electrical connection to the Drain or Source. If it does, it's like having a leaky faucet; the water (electricity) is constantly flowing, even when it shouldn't be.

Power Mosfet Field Effect Transistor Semiconductor De Vrogue.co

Static Testing

3. Resistance is Key

Let's talk about static testing. This involves testing the MOSFET when it's not powered up. This helps isolate potential issues with the component itself, rather than problems caused by the circuit around it.

With your multimeter set to resistance mode, measure the resistance between the Drain and the Source. In a normal MOSFET, this resistance should be relatively high when the Gate voltage is zero. However, if you see a very low resistance, close to zero, it suggests that the MOSFET is shorted and stuck in the "on" state. This is a common failure mode.

Next, apply a small voltage (typically a few volts) to the Gate. This should "turn on" the MOSFET, causing the resistance between the Drain and Source to decrease significantly. If the resistance remains high even after applying voltage to the Gate, it indicates that the MOSFET is not turning on properly, suggesting it's defective.

Imagine trying to open a door (turning on the MOSFET) with the wrong key (no Gate voltage). Nothing happens. But if the door is already wide open (shorted MOSFET) regardless of the key, you know something's wrong.

How To Test Mosfet In Circuit

Dynamic Testing

4. Beyond the Multimeter

Static testing is a good starting point, but it doesn't tell the whole story. Dynamic testing involves observing how the MOSFET switches under load. This is a more advanced technique that requires a signal generator and an oscilloscope. If you don't have these tools, don't worry; static testing is usually sufficient for identifying most defective MOSFETs.

With a signal generator, you can apply a square wave to the Gate of the MOSFET. This will cause the MOSFET to switch on and off rapidly. An oscilloscope allows you to observe the voltage waveform at the Drain. A healthy MOSFET should produce a clean, square wave at the Drain, with sharp transitions between the "on" and "off" states.

If the waveform at the Drain is distorted, noisy, or has slow transitions, it indicates that the MOSFET is not switching properly. This could be due to a variety of factors, including a damaged Gate, internal shorts, or excessive leakage current.

Think of it like testing the gears in a car. Static testing is like checking if the gears are physically present. Dynamic testing is like actually driving the car to see if the gears shift smoothly and efficiently.

Power Mosfet Testing At Chris Stevens Blog

Common MOSFET Failure Modes

5. What Makes Them Go Wrong?

So, what are the usual suspects when it comes to MOSFET failures? Overvoltage is a big one. Exceeding the maximum voltage rating of the Gate or Drain can cause catastrophic damage, leading to short circuits or open circuits. Think of it like overfilling a balloon; eventually, it's going to burst.

Overcurrent is another common cause. Exceeding the maximum current rating of the Drain can cause the MOSFET to overheat and fail. This is like trying to force too much water through a pipe; it'll eventually crack or burst.

Electrostatic discharge (ESD) is a silent killer of MOSFETs. Even a small static shock can damage the Gate insulation, leading to premature failure. That's why it's important to use proper ESD protection when handling MOSFETs, such as wearing an anti-static wrist strap.

Thermal stress is also a factor. Repeatedly switching the MOSFET at high frequencies can cause it to overheat over time, leading to gradual degradation and eventual failure. Proper heat sinking is essential for dissipating heat and extending the lifespan of the MOSFET.

Mosfet Simple Explanation At Susan Cochrane Blog

FAQ

6. Your Burning Questions Answered

Let's tackle some common questions you might have about troubleshooting MOSFET issues:

7. Question

Answer: Use a multimeter to measure the resistance between the Drain and Source. If the resistance is very low (close to zero), the MOSFET is likely shorted.8. Question

Answer: "Blown" is a general term that means the MOSFET has failed, usually due to overvoltage or overcurrent. It might be shorted, open, or have other internal damage.9. Question

Answer: Yes, but you need to ensure the replacement MOSFET has similar or better specifications, such as voltage rating, current rating, and Gate threshold voltage. Check the datasheets carefully.10. Question

Answer: Yes! always ensure that the circuit is properly protected against overvoltage and overcurrent conditions. Use proper heat sinking to dissipate heat, and handle MOSFETs with care to avoid ESD damage.