Marvelous Info About Is AWG The Same As Mm2

Decoding Wire Sizes

1. Understanding Wire Gauge Systems

Ever stared at a spool of wire and felt like you were deciphering ancient hieroglyphics? You're not alone! Wire sizes are often expressed in AWG (American Wire Gauge) or mm2 (square millimeters), and figuring out the relationship between them can feel a bit like learning a new language. Think of it as trying to understand the difference between Fahrenheit and Celsius — both measure temperature, but use different scales. AWG is primarily used in North America, while mm2 is more common in the rest of the world. So, is AWG the same as mm2? Not exactly, but they both describe the same thing: the cross-sectional area of a wire, which dictates how much current it can safely carry.

The key difference lies in how these measurements are derived. AWG is a logarithmic scale based on the number of dies used to draw the wire; the smaller the AWG number, the thicker the wire. Its a bit counterintuitive, I know! Think of it like golf: a lower score is better. On the other hand, mm2 is a direct measurement of the wire's cross-sectional area. So, a larger mm2 value means a thicker wire, making it a more straightforward system to grasp.

Therefore, while AWG and mm2 aren't directly interchangeable without a conversion, they both serve the essential function of indicating the size and current-carrying capacity of a wire. Understanding their relationship is crucial for safe and efficient electrical work. Imagine using a wire that's too thin for the intended current load — you risk overheating, melting insulation, and potentially starting a fire. Nobody wants that kind of excitement!

Think of it as this. You wouldn't use a garden hose to supply water for a fire truck, would you? Similarly, you need to make sure your wires are properly sized for the job they need to do. Whether that's expressed in AWG or mm2, it's important to know which is which!

The Conversion Conundrum

2. Bridging the Gap Between Measurement Systems

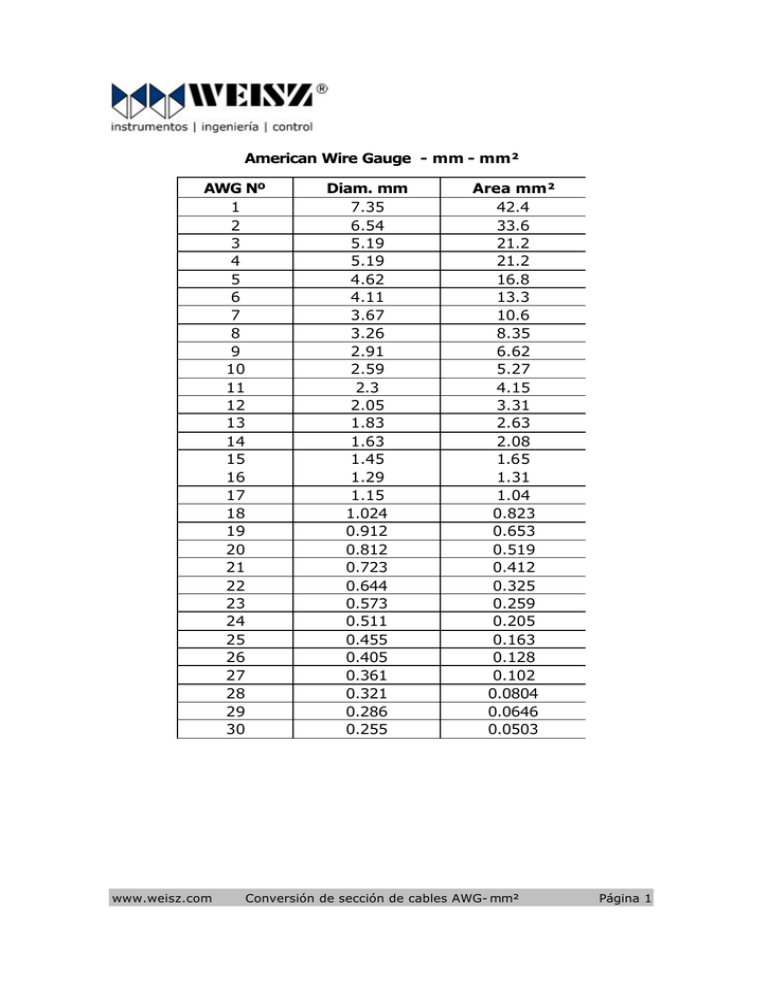

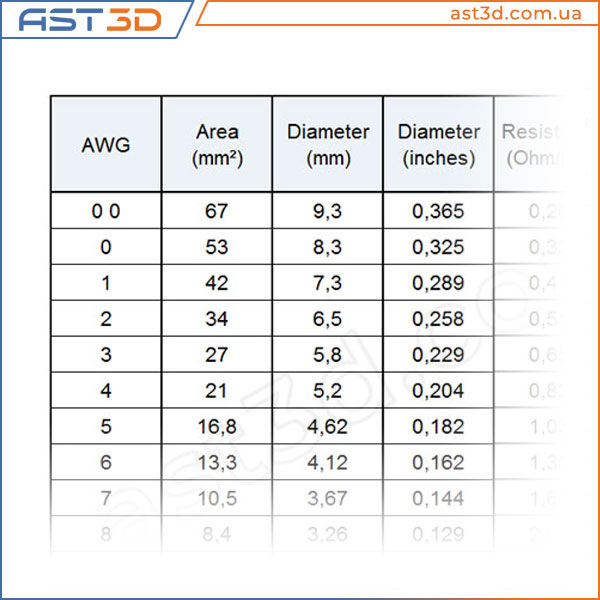

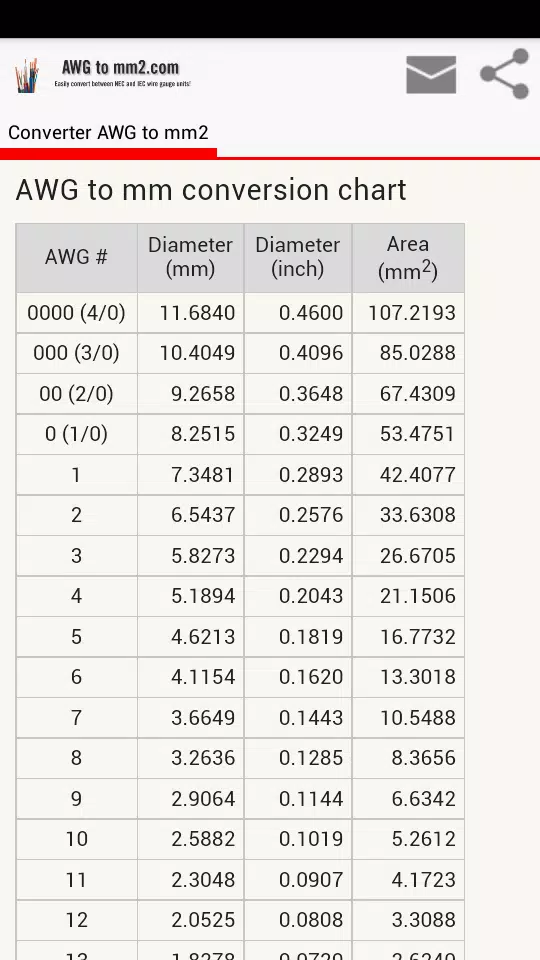

So, if AWG and mm2 are different scales for measuring the same thing, how do you convert between them? This is where things get a little mathematical, but don't worry, you don't need to be Einstein to figure it out. There's a formula for converting AWG to mm2, and vice versa. However, the easiest way is to use a conversion chart or an online calculator. These tools are readily available and can save you a lot of time and head-scratching. Just type "AWG to mm2 converter" into your favorite search engine, and you'll find plenty of options.

When using a conversion chart, you'll typically see a table listing AWG sizes and their corresponding mm2 equivalents. For example, 14 AWG wire is roughly equivalent to 2.5 mm2. It's important to note that these conversions are approximate, and there might be slight variations depending on the source. Always double-check your values and consult relevant electrical codes and standards for your specific application.

Why is this conversion important? Well, imagine you're working on a project that requires a specific wire size in mm2, but all you have on hand is wire labeled in AWG. Knowing how to convert between the two allows you to select the appropriate wire and ensure your project is safe and compliant. It's like having a universal translator for wire sizes!

Dont be afraid to use online resources to assist with these conversions. Accuracy is key here. Using the wrong size wire, even slightly, can lead to potential hazards. Take the time to ensure youve got the right match for your needs. Think of it like baking a little too much of one ingredient can ruin the whole cake!

Electrical Cable Size Awg To Mm2 At Eusebia Horton Blog

Why Does It Matter? Understanding Current-Carrying Capacity

3. The Importance of Wire Size

Okay, we've established that AWG and mm2 are just different ways of expressing wire size, but why does wire size even matter? The answer boils down to current-carrying capacity, also known as ampacity. Every wire has a limit to how much electrical current it can safely handle. Exceeding this limit can cause the wire to overheat, potentially melting the insulation and creating a fire hazard. Not exactly the kind of DIY project were aiming for!

The larger the wire (lower AWG number or higher mm2 value), the more current it can carry. This is because a larger wire has a lower resistance, allowing electricity to flow more easily without generating excessive heat. Think of it like a water pipe: a wider pipe can carry more water without increasing the pressure. Choosing the right wire size is therefore crucial for ensuring the safety and reliability of your electrical system.

Electrical codes and standards specify the minimum wire size required for different applications based on the expected current load. These codes take into account factors such as the type of insulation, the ambient temperature, and whether the wire is run in conduit or open air. Always consult these codes and standards before starting any electrical work. It's better to be safe than sorry, and following code ensures that your electrical system is up to par.

Consider an example: If you're wiring a high-power appliance like a refrigerator or air conditioner, you'll need a thicker wire than if you're wiring a low-power device like a lamp. Using the wrong wire size could lead to overheating, voltage drops, and even equipment failure. Properly sized wires are the unsung heroes of your home's electrical system, keeping everything running smoothly and safely.

Awg To Mm2 Google Search Solar Info, Chart, Oldbury

Beyond Size

4. More Than Just AWG and mm2

While AWG and mm2 are crucial for determining wire size, they aren't the only factors to consider when choosing the right wire for a job. Other important considerations include the type of wire (solid or stranded), the insulation material, the voltage rating, and the environmental conditions in which the wire will be used. It's like choosing the right tool for a specific task: a hammer is great for nails, but not so great for screws.

Solid wire is typically used for permanent installations, while stranded wire is more flexible and suitable for applications where the wire needs to be bent or moved frequently. The insulation material affects the wire's resistance to heat, moisture, and chemicals. Common insulation materials include PVC, Teflon, and rubber. The voltage rating indicates the maximum voltage that the wire can safely handle. Exceeding this rating can cause the insulation to break down and create a short circuit.

Environmental conditions also play a role in wire selection. For example, if the wire will be exposed to extreme temperatures, you'll need to choose a wire with a high-temperature insulation rating. If the wire will be exposed to moisture or chemicals, you'll need to choose a wire with appropriate corrosion resistance. Selecting the right wire for the specific application is essential for ensuring long-term reliability and safety.

Think of it as selecting clothing for the weather. You wouldn't wear a swimsuit in the winter or a parka in the summer, would you? Similarly, you need to choose a wire that's appropriate for the environment it will be used in. Don't underestimate the importance of these factors! A little extra attention to detail can save you a lot of headaches down the road.

Copper Wire Awg To Mm2 At Aidan Penton Blog

Practical Applications

5. Putting Knowledge into Practice

Now that we've covered the theory, let's look at some practical examples of how AWG and mm2 knowledge is applied in real-world scenarios. Imagine you're wiring a new outlet in your home. You'll need to determine the appropriate wire size based on the circuit breaker rating and the appliances that will be plugged into the outlet. Typically, 12 AWG (around 4 mm2) or 14 AWG (around 2.5 mm2) wire is used for general-purpose outlets.

Another example is automotive wiring. Cars use a variety of wire sizes for different circuits, ranging from small gauge wires for lighting to larger gauge wires for the starter motor. Knowing the current requirements of each circuit is crucial for selecting the correct wire size and ensuring the vehicle's electrical system functions properly. Often times, these ratings are given in either AWG or mm2, or sometimes both.

Industrial applications often require even more precise wire sizing due to the higher voltages and currents involved. For example, in a manufacturing plant, large gauge wires are used to power heavy machinery and equipment. Electrical engineers and technicians must carefully calculate the wire size needed for each application to prevent overheating and ensure safety.

Consider also renewable energy systems. Solar panels and wind turbines generate electricity that needs to be safely transmitted to batteries or the grid. This requires careful selection of appropriately sized wires, often with consideration for long distances and varying environmental conditions. The proper wire ensures efficient energy transfer and minimizes losses.

MM To AWG MM2 Chart Electrical4u, 59 OFF

FAQ

6. Frequently Asked Questions

Let's tackle some common questions about AWG and mm2 to solidify your understanding.

Q: Is a smaller AWG number a thicker or thinner wire?

A: A smaller AWG number indicates a thicker wire. It's a bit counterintuitive, but remember, it's like golf: lower is better!

Q: Can I use a wire with a lower ampacity than the circuit breaker rating?

A: Absolutely not! Always use a wire with an ampacity equal to or greater than the circuit breaker rating. Using a wire that's too small can create a fire hazard.

Q: Where can I find a reliable AWG to mm2 conversion chart?

A: Many online resources offer conversion charts. Just search for "AWG to mm2 conversion chart" on your favorite search engine. Make sure to cross-reference with a second chart just to be sure!

Q: Does the material of the wire affect its ampacity?

A: Yes, absolutely! Copper and aluminum are the most common wire materials. Copper has a higher ampacity for a given size compared to aluminum. When using aluminum wiring, it's crucial to increase the wire size to compensate for its lower conductivity.