Lessons I Learned From Info About What Is The Cohen Coon Method

PPT Chapter 6 PowerPoint Presentation, Free Download ID1748112

Deciphering the Cohen-Coon Method

1. What's the Deal with Process Control?

Alright, let's talk about process control. Sounds a bit dry, doesn't it? But trust me, if you're involved in anything from chemical engineering to running a brewery (and who isn't a little involved in that, right?), understanding how to tune your control loops is absolutely essential. Enter the Cohen-Coon method — a clever little technique for getting your processes running smoothly.

Imagine trying to brew a perfect batch of beer. Too hot, and you'll kill the yeast; too cold, and fermentation will stall. You need a way to maintain that sweet spot. That's where controllers come in. They're the brains behind the operation, constantly monitoring and adjusting variables like temperature, pressure, and flow rate.

But here's the rub: every process is different. What works for controlling the temperature in your coffee maker won't necessarily work for a massive industrial reactor. That's why we need methods like Cohen-Coon to fine-tune our controllers to the specific characteristics of our system. It's all about achieving that delicate balance between responsiveness and stability.

Think of it like driving a car. You want to be able to accelerate quickly when you need to, but you also don't want to slam on the brakes every time you see a squirrel. A well-tuned control loop is like a smooth, responsive driver who anticipates the road ahead. A poorly tuned one is... well, let's just say it involves a lot of swerving and near misses.

So, What Exactly Is the Cohen-Coon Method?

2. Breaking Down the Formula

Okay, let's get a little technical, but I promise to keep it painless. The Cohen-Coon method is a set of equations used to estimate the ideal settings for a PID (Proportional-Integral-Derivative) controller based on the open-loop response of your process. Open-loop response? That just means how your system reacts when you give it a step change in input, like suddenly cranking up the heat or opening a valve.

Essentially, you perform a step test on your process. You note down how long it takes for the process variable (like temperature) to start changing (that's the dead time or delay) and how quickly it reaches a new steady state (thats related to the time constant). These two values (delay and time constant) are then plugged into the Cohen-Coon formulas to calculate the proportional gain (Kc), integral time (Ti), and derivative time (Td) settings for your PID controller.

The magic of Cohen-Coon lies in its simplicity. It's a relatively easy method to implement, especially if you've already got some historical data on how your process behaves. It provides a good starting point for tuning your controller, giving you a decent first guess at the optimal settings.

Now, I know what you're thinking: "Formulas? Math? Ack!" But don't worry, there are plenty of online calculators and software packages that will do the heavy lifting for you. You just need to understand the basic concepts and be able to interpret the results.

Why Use Cohen-Coon? And When Should You Not?

3. The Pros and (Potential) Cons

The Cohen-Coon method boasts a few compelling advantages. First, as mentioned, it's relatively simple to implement. You don't need a Ph.D. in control theory to understand the basics and apply the formulas. This makes it a great option for quick and dirty tuning, especially when you're short on time or resources.

Second, it's based on the open-loop response of your process, meaning you don't need to shut down the entire system to get the data you need. You can often perform a step test while the process is still running, minimizing disruption to your operations. Plus, it can provide a decent starting point, reducing the trial-and-error inherent in controller tuning. Trial and error is fun...said no one ever managing a complex system.

However, Cohen-Coon isn't a silver bullet. One limitation is that it assumes your process can be reasonably approximated by a first-order plus dead-time (FOPDT) model. If your process is significantly more complex — for example, if it has significant non-linearities or higher-order dynamics — Cohen-Coon might not give you the best results.

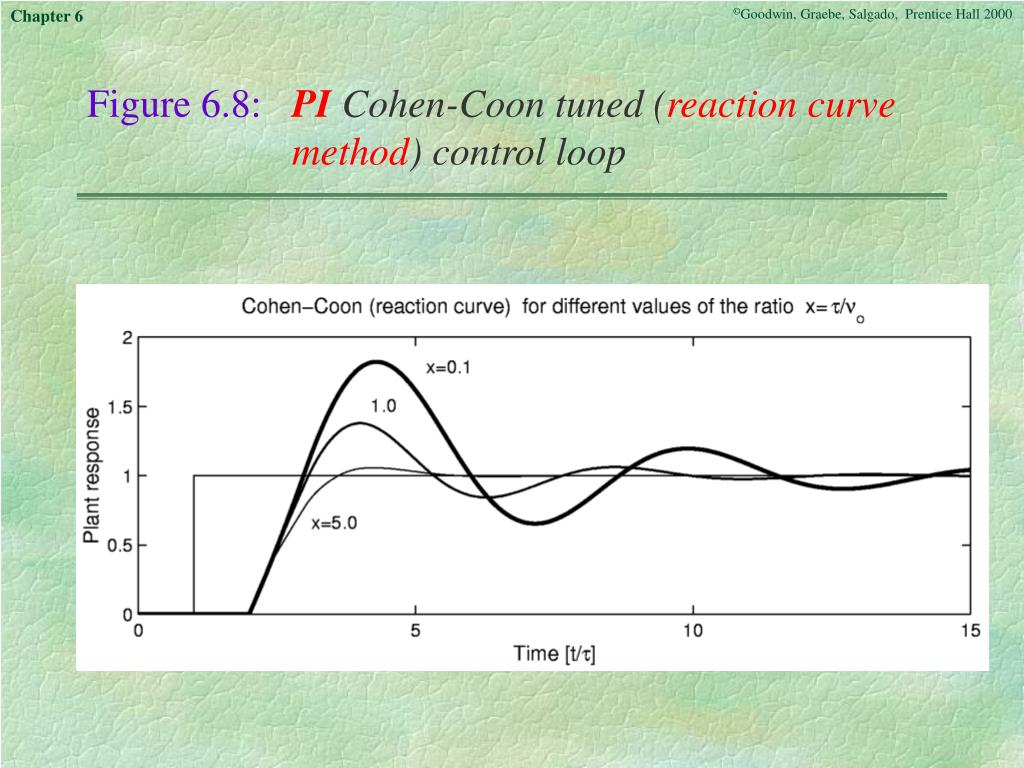

Another consideration is that the Cohen-Coon method tends to produce aggressive controller settings. This means your controller might be very responsive to changes, but it could also be prone to oscillations or instability. Always test your settings thoroughly and be prepared to make adjustments. It's like adding spice to a dish - a little adds flavor, too much ruins the meal. Controller tuning is a balancing act.

Solved Use The CohenCoon Method To Tune System. 1.

Putting Cohen-Coon into Action

4. From Theory to Practice

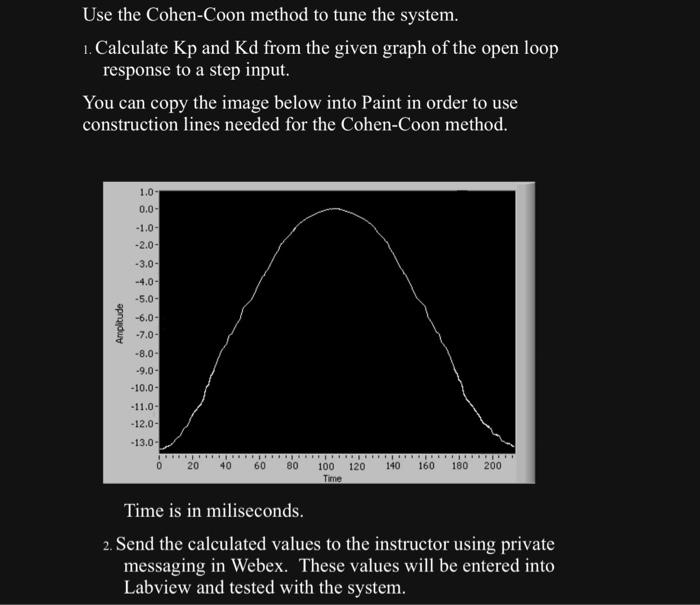

Alright, let's get our hands dirty and walk through the process of using the Cohen-Coon method. First, you need to perform a step test on your process. This involves making a sudden change to the input (e.g., changing the setpoint by a certain amount) and observing how the output responds over time.

Next, you need to analyze the resulting response curve. Identify the dead time (the time it takes for the output to start changing) and the time constant (a measure of how quickly the output reaches a new steady state). There are graphical methods and software tools that can help you with this.

Once you have these two values, plug them into the Cohen-Coon formulas to calculate the PID controller settings (Kc, Ti, and Td). These formulas can be found in most control engineering textbooks or online. Alternatively, use an online calculator to do the calculations for you.

Finally, enter these settings into your PID controller and test the performance. Monitor the response to setpoint changes and disturbances. If the response is too sluggish, increase the proportional gain (Kc) or decrease the integral time (Ti). If the response is too oscillatory, decrease the proportional gain or increase the integral time. Remember, fine-tuning is key!

PID Control On Arduino CohenCoon Method Applied System

Beyond Cohen-Coon

5. Expanding Your Control Toolkit

While Cohen-Coon is a valuable tool, it's important to remember that it's just one method among many. There are other tuning techniques out there, each with its own strengths and weaknesses. Ziegler-Nichols, for example, is another popular method that's similar to Cohen-Coon but uses different formulas.

Another approach is to use more sophisticated model-based tuning techniques. These methods involve developing a more detailed mathematical model of your process and using that model to design the controller. This can be more accurate than Cohen-Coon, but it also requires more effort and expertise. If you are working with something very sensitive, it would be worth doing extra research to see which is best.

Adaptive control is another interesting option. With adaptive control, the controller automatically adjusts its settings in response to changes in the process. This can be useful if your process is subject to significant variations over time, as it would allow more consistently smooth operations. However, it also adds complexity and requires very careful design.

Ultimately, the best tuning method for your process will depend on a variety of factors, including the complexity of the process, the desired level of performance, and the available resources. Don't be afraid to experiment with different methods and see what works best for you. And remember, always prioritize safety and stability.'s important to explore other tuning methods to have the best results.

1 Simulink Model For Cohen Coon Method Download Scientific Diagram

FAQ

6. Q

A: No, the Cohen-Coon method is most effective for processes that can be reasonably approximated by a first-order plus dead-time (FOPDT) model. It may not be the best choice for highly complex or nonlinear processes.

7. Q

A: A step test involves making a sudden change to the input (e.g., the setpoint) of your process and observing how the output responds over time. Record the resulting response curve to identify the dead time and time constant.

8. Q

A: The Cohen-Coon method is relatively simple to implement and provides a good starting point for tuning PID controllers. It's based on the open-loop response of your process, which means you don't need to shut down the entire system to get the data you need.

9. Q

A: The Cohen-Coon method assumes a first-order plus dead-time model, which may not be accurate for all processes. It can also produce aggressive controller settings, potentially leading to oscillations or instability. Test settings thoroughly, and adjust!